| Links to old reviews |

|

| P-36 "Cleveland Air Races" |

Brazilian

Hawk 75 |

| Finnish

Hawk 75 |

Hawk

gallery |

| Kit |

Kit box |

Part # |

Engine |

Variants | Notes |

| P-36 Pearl Harbor Defender |

Twin Wasp |

USAAC, Brazil |

Reboxed by Academy |

||

| French Hawk 75 |

Twin Wasp |

Two French aircraft |

Same plastic as above |

||

| Curtiss Mohawk |

Cyclone |

One British, one Chineese, one

Peruvian |

ONLY a Mohawk IV. For I, II, or

III, use one of the other two kits above (French or Pearl Harbor.) |

||

| Hawk 75M/N/O |

Cyclone |

One Siam (Thai,) one (or two)

Chineese, two Argentinian |

Underwing cannon included, as

well as side window "blanks" and a different wing bottom. |

||

| Allied Hawk 75 |

Cyclone |

Dutch (NEI,) SAAF, Peru, China |

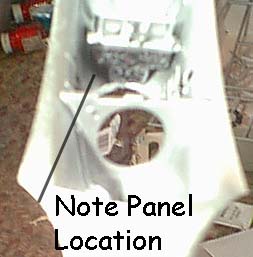

For starters, the

instructions would have you place the instrument panel far too far aft

in the cockpit, sticking out under a "T" shaped support frame. That

frame doesn't always exist in the real aircraft (it does in French

hawks, for instance - it's used to support some reflector sights) and

the instrument panel is under a coaming. Add to that the pain the panel

can be when trying to fit it into a fuselage half, and you see an

obvious problem.

For starters, the

instructions would have you place the instrument panel far too far aft

in the cockpit, sticking out under a "T" shaped support frame. That

frame doesn't always exist in the real aircraft (it does in French

hawks, for instance - it's used to support some reflector sights) and

the instrument panel is under a coaming. Add to that the pain the panel

can be when trying to fit it into a fuselage half, and you see an

obvious problem.| P-36 variants |

Wing guns | Which holes to open |

Engine |

Notes |

| P-36A |

None | None | Standard USAAC model. |

|

| XP-36B |

None | 1,100 HP R-1830-25 |

Engine testbed, converted P-36A

(38-20). Reconverted to P-36A. |

|

| P-36C |

Inner | Round hole (shell eject "bucket") | R-1830-17 |

38-85 testbed, 30 from last of

P-36A order built as P-36C |

| XP-36D |

Both | Rectangular holes | 174th P-36A converted (38-174)

with four .30 cal in wing. Later nose armament changed to two .50 cal. |

|

| XP-36E |

Both | Rectangular holes | 147th P-36A (38-147) with four

.30 cal MGs each wing. Nose .50 inoperable. |

|

| XP-36F |

Underwing cannon* | Round hole | 38-172. One 23mm Madsen cannon

under each wing. |

|

| P-36G** |

Both | Rectangular | Cyclone |

See note below |

| YP-37 (Hawk 75i) |

Allison inline |

13 built for service test |

||

| Hawk 75J |

Turbo-supercharged Twin Wasp |

Not built |

||

| Hawk 75K |

1200 Hp Twin Hornet |

Not Built |

||

| Hawk 75P |

Allison Inline |

XP-40 |

||

| Hawk 75R |

Standard engine |

Supercharger mounted under nose,

intercooler under trailing edge of the wing. Refitted with Cyclone, used

as demonstrator with NX-22028 markings |

||

| Hawk 75S / XP-42 |

P&W R-1830-31 (Twin Wasp) |

Fourth P-36A (38-4) for cowl

streamlining and (later) flying tail experiments, retained by Curtiss,

used by NACA. Washable camo used for 1939 War games. |

| Export model | Other names | Wing guns | Engine | User | Notes |

| 75A-1 | Mohawk 1 | Inner | Twin Wasp as P-36A | French, RAF |

|

| 75A-2 | Mohawk II | Both | Twin Wasp | French, RAF |

|

| 75A-3 | Mohawk III | Both | Improved Twin Wasp | French, RAF |

|

| 75A-4 | Mohawk IV | Both | Cyclone | French, RAF |

|

| A-5 | ? | Cyclone | China | One built | |

| A-6 |

Inner |

Twin Wasp |

Norway, Germany, Finland |

||

| A-7 |

Cyclone |

Netherlands East Indies |

|||

| A-8 |

All |

Cyclone |

Norway, USAAC, Peru |

ADF "Football," short wheel

pants. USAAC as P-36G. Ring/Bead sight, no internal gunsight |

|

| A-9 |

Mohawk |

Cyclone |

Iran (to Britain) |

Britain took over before

delivery to Iran. Sent to India as Mohawk. |

| Model |

Other name |

Wing Guns |

Engine |

Users |

Notes |

| Model 75H |

Hawk 75 |

Inner |

Cyclone |

Demonstrator (China, Argentina) |

Two built - Natural metal -

presented to Claire Chennault (NR-1726) . Argentina - NR-1276 - in

Argentinian markings. 300 lbs of bombs underwing. |

| Model 75M |

Inner |

Cyclone |

China |

112 made, production version of

75H - most destroyed in China |

|

| 75N |

Both |

Cyclone |

Siam (Thailand) |

||

| 75o |

Three per wing |

Cyclone |

Argentina |

30 shipped, 200 made under

license in 1940 |

|